Precision Mechanical Design Services for Optimal Performance

In the modern engineering world, precision and efficiency go hand in hand. Industries today demand more than just functioning mechanical systems—they require designs that ensure optimal performance, reduce downtime, and increase productivity. That’s why precision mechanical design services for optimal performance have become a cornerstone in advanced engineering projects across industries.

Whether you’re in aerospace, medical technology, automotive, or industrial automation, having tailored and accurate design services can make all the difference. Let’s explore how these services are shaping modern engineering and how your business can benefit from them.

What Are Precision Mechanical Design Services?

Precision mechanical design services for optimal performance involve the development of mechanical components and systems that meet exact specifications. These designs are based on advanced calculations, 3D modeling, simulation testing, and manufacturing feasibility.

This is not a one-size-fits-all approach. Instead, precision design ensures every mechanical detail—size, weight, tolerance, material, and stress factor—is carefully engineered to perform at its best. This results in reliable, efficient, and safe mechanical systems built to meet industry-specific requirements.

Why Precision Matters

Precision is more than just making parts fit—it’s about maximizing functionality and minimizing risk. Here’s why precision mechanical design services for optimal performance are vital:

- Improved reliability: Reduces wear, vibration, and system breakdowns.

- Enhanced product lifespan: Optimized parts last longer and require fewer repairs.

- Efficient energy usage: Mechanical systems run more smoothly and consume less energy.

- Safety compliance: High-precision parts meet international safety and regulatory standards.

- Increased productivity: Equipment performs better and processes run faster.

By focusing on accuracy and detail, these services ensure your mechanical systems achieve the best possible performance.

Key Components of Precision Mechanical Design

To deliver precision mechanical design services for optimal performance, engineers must consider multiple factors. The process includes:

1. Concept Development

Engineers begin with a deep understanding of the client’s needs and application. They assess operational goals, environments, stress limits, and material requirements.

2. CAD Modeling

Using software like AutoCAD, SolidWorks, or Creo, engineers create detailed 2D and 3D models of components and systems, ensuring precise geometries and tolerances.

3. Tolerance Analysis

Every component must fit and function perfectly. Tolerance analysis ensures that parts remain within acceptable variations during manufacturing and assembly.

4. Simulation Testing

Finite Element Analysis (FEA) and motion simulation help identify potential issues, such as deformation, fatigue, or heat stress, before physical prototypes are created.

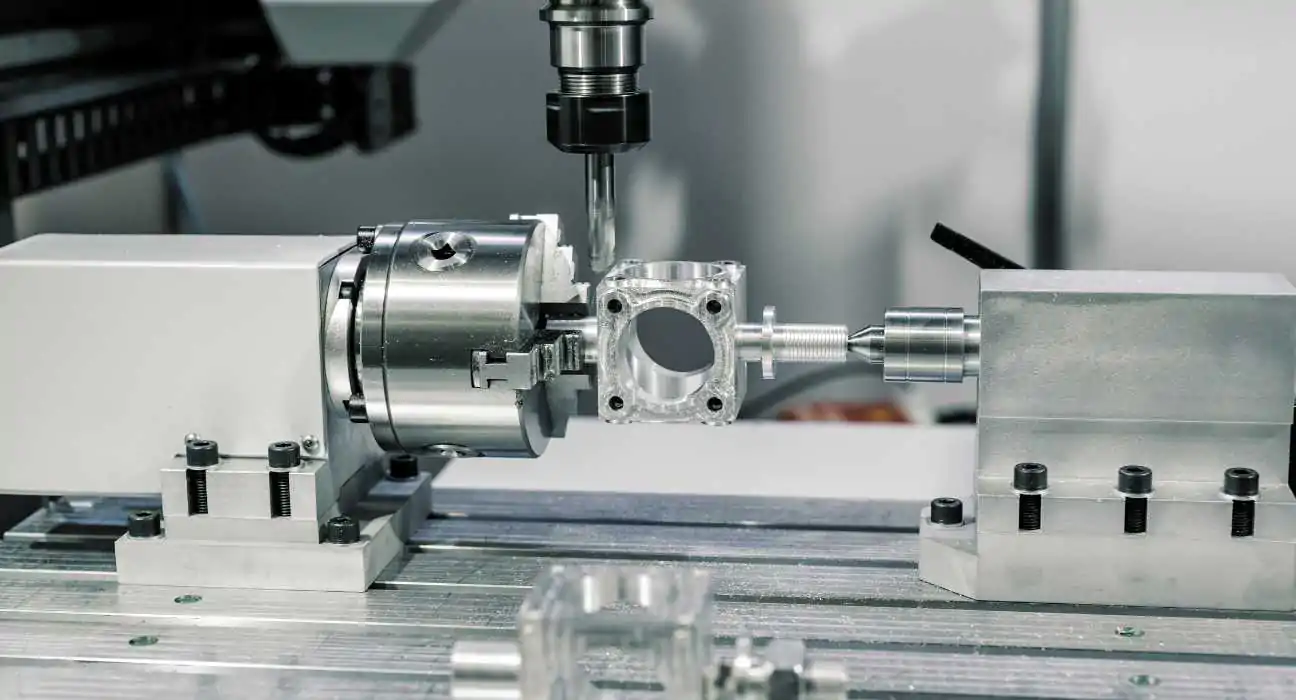

5. Prototyping

Rapid prototyping methods, including 3D printing and CNC machining, help engineers create physical versions for real-world testing and validation.

6. Design Optimization

Designs are refined based on test results to maximize durability, performance, and manufacturability.

This comprehensive approach ensures that all design factors are considered to meet the demands of precision mechanical design services for optimal performance.

Applications Across Industries

Precision mechanical design services are used in virtually every industry where mechanical systems play a role. Here are a few examples:

Aerospace

Aircraft systems require flawless design to ensure safety and efficiency. Even the smallest miscalculation can lead to performance loss or failure. That’s why aerospace companies rely heavily on precision mechanical design services for optimal performance.

Medical Devices

Medical tools and machines must perform consistently in critical situations. Precision ensures proper calibration, accurate readings, and dependable usage in surgical or diagnostic equipment.

Automotive

From engine components to braking systems, automotive manufacturers use these services to meet strict performance and emissions standards while maintaining driver safety.

Industrial Automation

Robots, conveyors, and control systems in manufacturing rely on precise movement and load-bearing capabilities. This makes mechanical design accuracy essential for smooth operations.

Renewable Energy

Wind turbines, solar trackers, and hydro systems operate under extreme conditions. With proper mechanical design, they can deliver maximum output with minimal maintenance.

Benefits of Precision Design Services

Here are the key benefits businesses experience when they invest in precision mechanical design services for optimal performance:

- Reduced operational costs: High-quality components mean fewer breakdowns and maintenance needs.

- Faster time to market: Accurate designs minimize trial-and-error phases and speed up development.

- Consistency in manufacturing: Designs that align with production methods ensure consistent product quality.

- Customization and scalability: Solutions can be tailored to specific applications and scaled as needed.

- Competitive advantage: Innovative, high-performance products stand out in the marketplace.

In short, precision design is not just an engineering choice—it’s a strategic advantage.

The Design Workflow

Understanding the workflow can help you see how precision is embedded into each step of the process. Here’s a general outline:

- Requirements Gathering – Understanding functionality, load limits, and user expectations.

- Conceptual Design – Exploring initial ideas and developing engineering sketches.

- Detailed CAD Design – Creating fully rendered 3D models with exact dimensions and tolerances.

- Simulation and Testing – Using digital tools to analyze real-world forces.

- Prototyping and Fabrication – Building early-stage models for hands-on evaluation.

- Design Refinement – Adjusting features based on performance feedback.

- Manufacturing Support – Ensuring designs are compatible with production methods and quality controls.

This step-by-step process is integral to providing precision mechanical design services for optimal performance that meet both technical and business goals.

Choosing the Right Design Partner

Finding the right engineering team is key to unlocking the full potential of precision mechanical design. When selecting a design partner, consider the following:

- Experience in your industry

- Strong portfolio of past designs

- Expertise in CAD and FEA tools

- Commitment to quality and communication

- Prototyping and testing capabilities

- Knowledge of regulatory requirements

A trusted provider of precision mechanical design services for optimal performance should function as an extension of your team, offering tailored solutions that align with your goals.

Case Study: Custom Gearbox Design

Challenge: A packaging machinery company needed a gearbox that could operate at high speeds with minimal heat generation.

Solution: The engineering team used precision mechanical design services for optimal performance to develop a new gearbox with:

- Advanced gear ratios

- Improved lubrication systems

- Enhanced thermal coatings

Results: The machine’s efficiency improved by 22%, and overheating issues were completely resolved, reducing downtime by 40%.

This is just one example of how customized precision design can transform mechanical systems and operational efficiency.

Future Trends in Mechanical Design

As technology continues to evolve, so do the tools and methods used in mechanical engineering. Future trends that will influence precision mechanical design services for optimal performance include:

- AI and machine learning: Automated design optimization through intelligent software.

- Digital twins: Real-time performance monitoring of virtual replicas.

- Eco-conscious design: Emphasis on energy efficiency and sustainable materials.

- Smart components: Sensors embedded in mechanical parts for live diagnostics.

- Additive manufacturing: Enhanced flexibility in part design and prototyping.

These innovations are driving mechanical design into a new era of speed, accuracy, and efficiency.

Final Thoughts

Precision mechanical design services for optimal performance are essential in today’s competitive and fast-moving industries. Whether you’re building a medical device, upgrading an assembly line, or designing next-gen transport systems, accurate and tailored design is the foundation of success.