Reverse Engineering Services: Unlocking Innovation from Existing Products

Reverse engineering services are changing the way organizations innovate, repair, redesign and reproduce their products in any industry. Reverse engineering is being used by business experts to learn the organization, operation, and style of already existing products, including anything as varied as industrial gear and auto parts, historical components and consumer products, etc.

They no longer have to guess on how a product was manufactured or use ancient blueprints to develop a product, they now consult professional reverse engineering services to produce precise 3D models, 2D drawings and technical data. It is an effective product development, quality control, and digital archiving solution and a way of reducing costs.

What is Reverse Engineering Services?

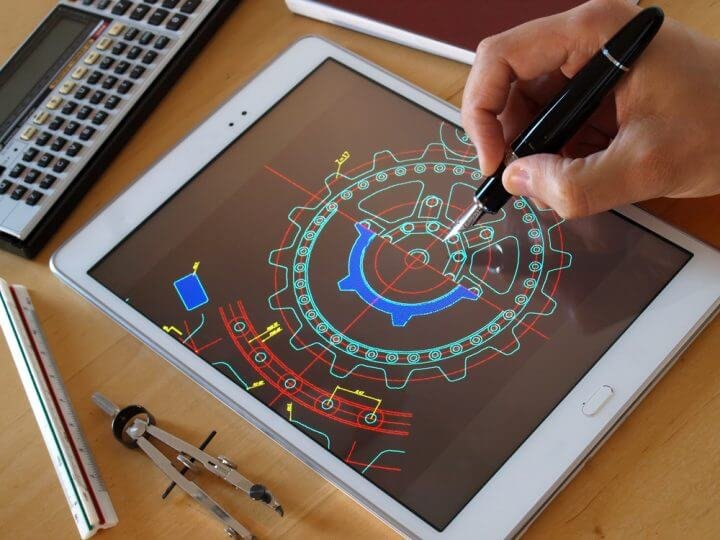

Reverse engineering services is a process that breaks down the physical product to obtain the design of information, its measurements, and specifications in which it operates. The common tool utilized in this process include 3D scanners, CMM machines or by measuring manually and later inputting CAD modeling to redesign the product digitally.

Reverse engineering and services are used by companies that do not have the design files of the original product, wish to analyze the product of competitors, wish to re-design obsolete pieces or improve the current products. A final thought about reverse engineering is that regardless of whether it is to duplicate or improve or redesign the first thing is to have the blueprint that is required and then one can proceed confidently.

The Reasons Why the Reverse Engineering Services Are Important Nowadays

Technology is changing fast and in the process, business organizations find it more difficult to undergo maintenance or upgrade to replace obsolete equipment and products. The reverse engineering services represent one of the solutions which provide implementation of physical components in the form of useful digital forms. Such services are particularly useful in the following occasions:

- Authentic CAD draws go out-of-date

- There is the lack of OEM support anymore

- There is need to replace custom or legacy parts

- There is need of competitive analysis

RE services are capable of accelerating the development cycle, enhancing reliability of products and having total control over the current designs. They connect the physical and the online world.

The Way Reverse Engineering Services Work

The process of reverse engineering begins with the physical geometry of a part either measured or scanned. This is the way the professional reverse engineering companies usually work:

- Data Collection- Scanning or laser scanners are used or CMM, any other metrology equipment is used to scan or measure the part in 3D surfaces.

- Cloud Processing Point cloud Point cloud Processing – Raw scan data is cleaned up, and turned into a point cloud or mesh model.

- 3D CAD Modeling- The scanned data is used to create a CAD model that will either be a parametric model or based on the surface.

- Drawing Generation- dimensions, tolerances and technical drawings are generated based on the model.

- Analysis & Validation- The last CAD model will be checked of its accuracy and compatibility.

- File Delivery Final files are provided in such forms as STEP, IGES, DWG, or STL to be ready to produce or document.

The reverse engineering services workflow and its process put in place to make sure design data is usable, manufacturable, and descendant of accuracy.

The Industries which Enjoy Significance of Reverse Engineering Services

Reverse engineering services are a myriad of industries that seek to prolong product lifecycle, enhance innovation as well as resolve technical issues:

- Automotive- Regenerate or copy car parts, engine parts and custom accessories.

- Aerospace: the digitalization of flight-relevant elements or redesign outdated systems.

- Manufacturing -Advancement of industrial machines, equipment, and manufacturing parts.

- Medical Devices – study and replicate surgical equipment or medical parts.

- Oil and Gas Recreate valve assemblies, pump component or fittings with no drawings.

- Consumer Electronics- Get to know about product architecture or learn the product teardown.

- Defense- Intervene and replace aged army equipment.

- Re-engineering services are particularly useful in cases where one has to work on older, aged or rare parts that are out of supply chains.

Advantages of Reverse Engineering by Professionals

Companies which invest in reverse engineering services attain competitive advantage by:

- Cost Savings -An expensive tooling or part sourcing is avoided through recreating what is already available.

- Product Innovation- Take what has been used and build on a better more advanced design.

- Speed to Market Reverse-engineered components provide speed to prototyping and development.

- Digital Archive Creation: Take paper based assets and make copies in electronic files to be referenced later.

- Quality Enhancement- Study and upgrade the bad or obsolete components.

- Manufacturing Readiness – Obtain CAD files in a format that can run CNC, 3D printing or injection molding.

The reverse engineering services facilitate the development of smarter, faster, and cheap products.

The Reverse Engineering Services Tools and Software

Reverse engineering services are professional and have a high level of accuracy: to achieve it, advanced hardware and software are utilized:

- 3D Scanners Structured light scakers, laser scanners or CT scanners can produce high detail surface geometry.

- CMM Machines- Coordinate Measuring Machines These machines are utilized to make accurate measurements and Geometry.

- CAD Software – SolidWorks, CATIA, NX and Autodesk Inventor are programs that build precise models.

- Tools Mesh Editing Tools There is software, such as Geomagic Design X and MeshLab, to process scan information.

- Reverse-Engineering and CAM Integration- Reconstructions are streamlined to machining or mold making and 3D printing.

These equipments enable service providers to scan real-life objects into superior digital copies that can be used in any project.

In the real world uses of reverse engineering services.

Both strategic and tactical reverse engineering services come in. It has some application in the real world such as:

Legacy Part Replacement- A manufacturer of HVAC equipment reverse-engineered a legacy bracket saving thousands of dollars on part sourcing.

Product Redesign A competitor had developed a unique and innovative casing (in the case of a consumer electronics product) and the company copied the parts and reconstructed the casing in such a way that it oriented better towards cooling and durability.

- Failure Analysis – An industrial company performed a reverse engineering application to observe a worn out gear and re- design it to have additional resistance to wear.

- Prototyping – A new start-up built a handmade mock-up into a working CAD design that cut lead time by weeks through reverse engineering a prototype into a production design.

These are just some of the ways that reverse engineering services make quantifiable value to companies in any industry and any product life cycle.

Preventing the everyday hurdles related to reverse engineering services

In absence of knowledge in reverse engineering services, problems such as ruin of data, wrong dimensions or even unworkable models may arise where services are rendered in-house. These issues are avoided when working with professionals as they guarantee:

More accurate Methods of Measurement- The tools and experts that are used being certified.

- Dimensional Accuracy -Models are very precise.

- Clean models CAD Well: No duplicated surfaces, and bad geometries.

- Compatibility- Your manufacturing systems and Software correspond with deliverables.

- Speed and Scalability- Projects are delivered exactly when they must be and to whatever specification you need.

- Quality reverse engineering services offer technical skills and support of specialized tools to achieve perfect outcomes.

Selecting an Ideal Service Provider in Reverse Engineering

When you are thinking of outsourcing reverse engineering, seek provider with:

- Experience Within Yours Industry- Experience with the product types and materials used by you.

- Full-Service Abilities – Scanning and modeling through prototyping and production.

- High-Accuracy Equipment-Utilization of sophisticated 3d scanners and CMM machines.

- Flexible file formats- provide files in DWG, STEP, STL, or native CAD format.

- Fast Turnaround Faster production without losing quality.

- Data Confidentiality – Safe management of your parts and files under NDA.

Mech CAD Drafting will provide every one of them and will enable you to reverse engineer more intelligently and quicker than ever before securing your intellectual property.